Premium plastic packaging, coupled with preservation methods for each product, is decisive to its contents.

ULTRA-HIGH BARRIER 9-LAYER FILMS:

Premium plastic packaging, coupled with preservation methods for each product, is decisive to its contents.

Targets natural food preservation just as “Skin keeps a ripe fruit from harm.”

Nine-layer (multi-layer) films

We have done research and marketing on different kinds of multi-layer packaging, compound nine-layer packaging to preserve food from cattle and poultry, seafood, luxury produce and packaging which can cushion products from absorbing oil and lubricants or pesticides in liquid form.

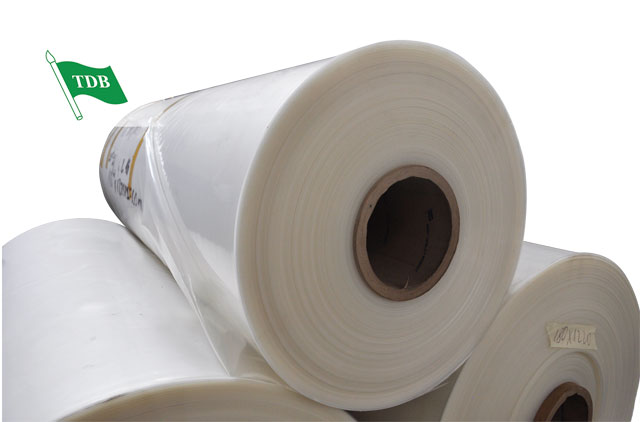

Rolls of uncut nine-layer plastic sheets

Nine-layer high barrier packaging has brought about a new, innovative packaging capable of forming a barrier against oxygen considerably better than conventional multi-layer packaging.

Preserving products as follows:

- Has better oxygen barrier (O2TR) and anti-absorption (WVTR) functions than compound filmed packaging thanks to the oxygen barrier layers such as PA, EVOH, PET,and PVDC

- Highly compatible with potential customers’ varied preservation needs. Therefore quality precisely meets customers’ quality requirements, with prices in accordance to the quality it has brought.

- Cut customers’ food preservation costs. Thanks to the superhigh barrier the nine-layer plastic packaging boasts, food stay fresh longer without using too many expensive preservatives into meat or fish. In addition, freezers and fridges save considerable amounts of electricity as clients only need to use suitably cold temperature for each product to fully retain their quality, with expiry date lengthened by twofold or threefold compared to in the past.

Therefore the nine-laer plastic packaging will help boost the value of processed products in business.

A worker is packing plastic bags into boxes

COMMON APPLICATIONS OF NINE-LAYER PACKAGING IN SEAFOOD PROCESSING

1/ HIGH BARRIER PACKAGING TO PRESERVE FRESH FISH AND OTHER KINDS OF SEAFOOD:

New methods in vacuum packaging have opened new opportunities for seafood preservation packaging in storing fresh fish in processing and retail distribution procedures. Vacuum nine-layer packaging ensures premium preservation and thus keeps seafood fresh and delectable either in handy plates or deep-vacuum shape-fixing packaging.

An assembly line of plastic bags

Nine-layer shape-fixing films are used in automatic Form Fill Sealing assembly lines.

- Easily fixing plate walls, with tightly sealed lids and continual vacuum pumping on the Form Fill Sealing machines (FFS).

- High packaging efficiency

- Hygienically ensured

- Preservation packaging is used with a wide array of products, ranging from fish, meat to produce.

- Determine Product weight precisely, dividing portions, and creating product packaging right on the packing line

2/ VACUUM SKIN PACKAGING (VSP):

Features:

- Used as skin packaging for fresh fish or fish or meat products which are added with colors or spices, or processed seafood including fillet, fish, crab, powder-coated crab, crab with spices.

- Used as transparent top films welded onto trays for convenience and aesthetical purposes when storing thawed fresh fish or processed fish or shrimp with spices added.

- Thaw the product right on the trays so that it can be preserved in chilly sections at supermarkets or household fridges.

- Lengthen expiry dates of processed products thanks to the oxygen barrier property of the films.

Benefits of Skinpack:

- Does not create pipe effects as the packaging is tightly wrapped around the product

- Highly suitable for fresh meat and fish

- Decrease cold temperature when quick freezing deeply frozen products. Is Therefore highly cost-effective for deeply frozen products

- Thaw the products right inside the packaging

- High barrier packaging is used for soft processed foods and liquids. For instance, packaging for processed meat, fish for quick consumption, trays or trays or jars with skinpack to store different kinds of sauces.

- Lengthen expiry date for processed meat. Specifically around eight weeks for smoked meat and processed meat, and six weeks for fresh meat. Our company can also cater to clients’ needs for longer use duration in preserving fish and meat.

- Highly modern as the product creates eye-catching 3D effects. And is perfect as for displaying products at supermarkets as the transparent packaging allows market goers to see the products inside.

3/ THREE-RIM PACKAGING PRODUCED FROM COEX NINE-LAYER FILMS FOR FRESH MEAT, SEAFOOD, DRIED MEAT AND FISH SOAKED IN SPICES

Different features in product preservation compared to PA bags with PE drying

- Withstand deeper vacuum pumping force thanks to the physical properties of coex nine-layer films which are far superior than compound packaging.

- Have better anti-penetration capacity when quick freezing meat and fish.

- Flexible, soft packaging which is also highly tough and durable at welding points so that they are unlikely to come off during vacuum pumping, and can withstand shock during shipping better.

- The product preservation capacity is far superior to PA compounded PE films thanks to multiple PA and EVOH layers.

- A wide array of bags with diverse applications which suit clients’ different packaging needs. For example, anti-contamination bags used for fresh fish and thermally pasteurized bags.

Multi-layer plastic film production machines

Trieu Du Bon Plastic Production Co. has boldly invested in the Canada-imported technology to produce 9-12 layer compound films to best cater to clients’ demands. This technology to create multi-layer compound films has turned out packaging products which stand out for their preservation effectiveness for clients’ items.

A Multi-layer plastic film production machine which is directly imported from Canada

A Multi-layer plastic film production machine which is directly imported from Canada

A Multi-layer plastic film production machine which is directly imported from Canada

Please contact directly for best prices:

Trieu Du Bon Plastic Production Co. Ltd.

Address: Lot numbered 15-17, No. 1 Street, Tan Tao Industrial Zone, Binh Tan District, HCMC

Website Address: www.trieudubon.com.vn

Phone: 083.9699.117 - 083.9699.118

Fax: 083.9603.541